Introduction:

Steel rolling mills are the unsung heroes of the manufacturing world, silently shaping raw steel into the sturdy building blocks that underpin our modern society. From skyscrapers to automobiles, the products of these mills form the backbone of numerous industries.

| Briefly introduce the concept of steel rolling mills and their significance in the steel manufacturing industry. |

| Highlight the importance of steel rolling in shaping raw materials into various forms, contributing to numerous industries worldwide |

What are Steel Rolling Mills?

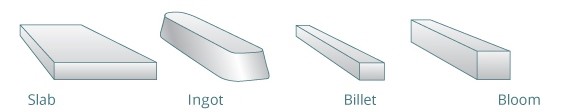

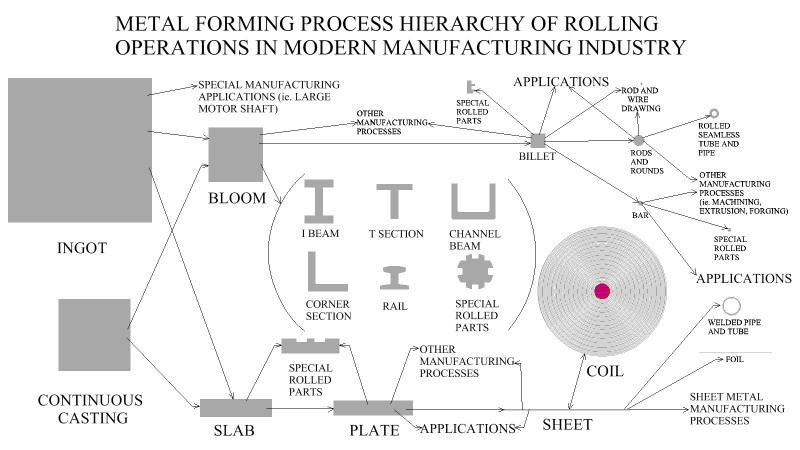

Define steel rolling mills and their primary function in the steel production process. Explain how raw materials such as slabs, ingots, bloom, or billets are processed through rolling mills to create different shapes, sizes, and thicknesses of steel.

The Operations within a Steel Rolling Mill

- Discuss the fundamental operations within a rolling mill, such as heating, rolling, and cooling.

- Explain the different types of rolling processes: hot rolling and cold rolling, emphasizing their distinctions in temperature, speed, and end product characteristics.

Types of Steel Rolling Mills

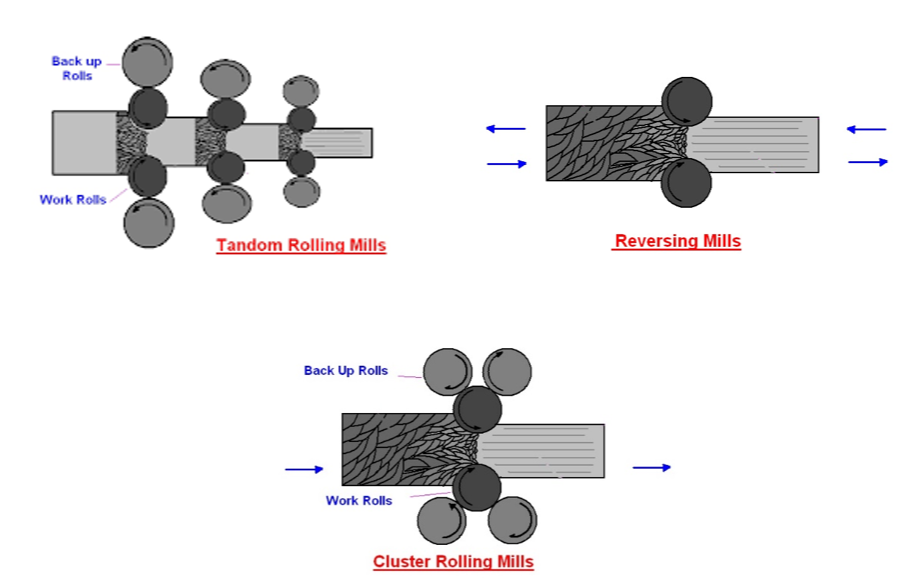

- Describe various types of rolling mills, including tandem mills, reversing mills, and cluster mills.

Applications and Products

- Highlight the diverse range of products that result from steel rolling mills, such as sheets, bars, rods, rails, and structural shapes.

- Discuss the industries that heavily rely on these rolled steel products, including construction, automotive, aerospace, and manufacturing.

Operations within a Steel Rolling Mill:

- The operations within a steel rolling mill encompass a meticulous choreography of heating, rolling, and cooling. Hot rolling involves heating the steel well above its recrystallization temperature, allowing for easier shaping. In contrast, cold rolling occurs at room temperature, producing steel with tighter tolerances and improved surface finish.

Applications and Products:

- The products derived from steel rolling mills are incredibly diverse, ranging from thin sheets used in automotive panels to robust beams for construction. These products serve industries such as infrastructure, transportation, machinery, and consumer goods, showcasing the versatility of steel rolling.

Technological Advancements in Steel Rolling Mills:

- Advancements in technology have transformed steel rolling mills into hubs of innovation. Automation and computerized controls have optimized precision and efficiency, while predictive maintenance techniques have minimized downtime, enhancing overall productivity.

Technological Advancements in Steel Rolling Mills

- Explore modern advancements in technology that have enhanced the efficiency, precision, and sustainability of steel rolling mills.

- Discuss innovations like automation, computerized controls, and predictive maintenance that have revolutionized the industry.

The Future of Steel Rolling Mills:

- Steel rolling mills continue to evolve, with a relentless pursuit of efficiency, precision, and sustainability. The future holds promises of further technological advancements, greener practices, and increased integration with digital technologies for a smarter and more sustainable manufacturing process.

Environmental Impact and Sustainability

- In an era focused on sustainability, the steel industry has made strides in reducing its environmental footprint. Efforts include optimizing energy consumption, adopting greener practices in production, and implementing recycling initiatives to minimize waste.

- Address the environmental considerations within steel rolling mills, focusing on energy consumption, emissions reduction, and waste management strategies.

- Highlight initiatives adopted by the industry to minimize environmental impact and promote sustainability.

Conclusion: The Future of Steel Rolling Mills

- Summarize the crucial role of steel rolling mills in shaping the steel industry and various sectors worldwide.

- Discuss potential future developments, innovations, and advancements expected in the field of steel rolling technology.

Closing Thoughts

- Encourage readers to explore further the world of steel production and its significance in our everyday lives.

- Invite engagement, comments, or questions from readers to encourage discussion and interaction.

- Feel free to elaborate on each section, add statistics, case studies, or real-life examples to make the blog more informative and engaging for the readers.

- Understanding the intricacies of steel rolling mills unveils the craftsmanship and technology behind the steel products that form the backbone of modern civilization. It’s a world where innovation meets necessity, shaping our world one roll at a time.

- Feel free to expand on each section, incorporating specific examples, case studies, or interviews with industry experts to add depth and credibility to the content. Additionally, including visuals like diagrams or images of steel rolling mills could further enhance the reader’s understanding.