Steel is one of the most widely used materials in the world, forming the backbone of infrastructure, transportation, and manufacturing industries. However, traditional steel production is highly energy-intensive and contributes significantly to carbon emissions. As sustainability becomes a global priority, the steel industry is undergoing a transformation, adopting eco-friendly innovations to minimize its environmental footprint. This blog explores the importance of sustainable steel production and the key innovations shaping a greener future.

The Environmental Impact of Traditional Steel Production

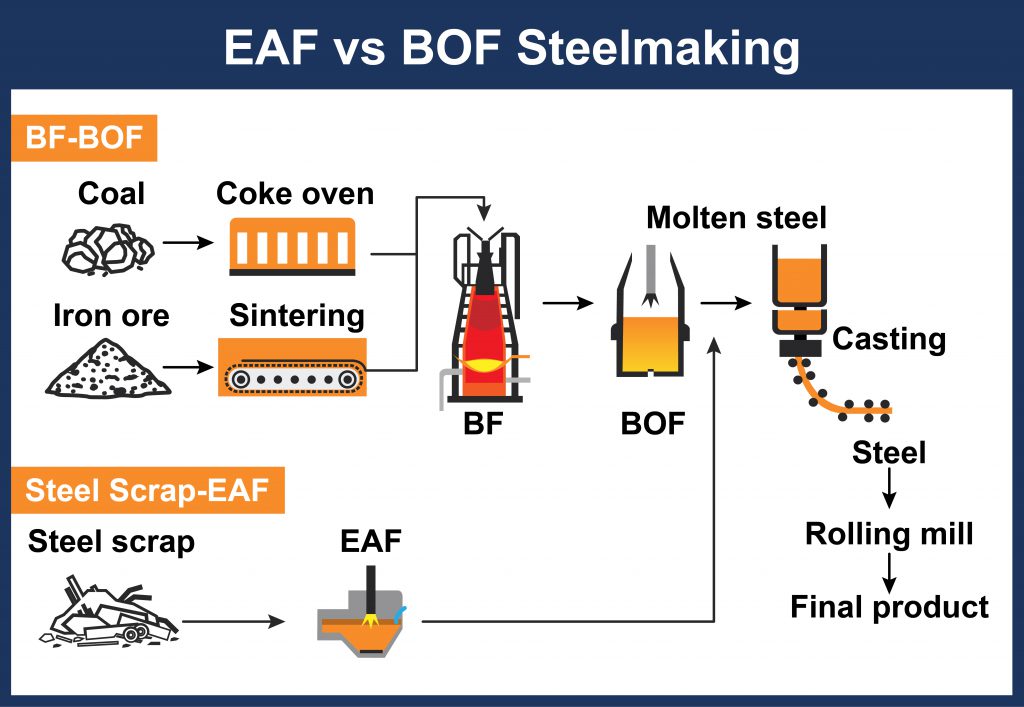

Conventional steel manufacturing relies heavily on fossil fuels, particularly coal, through the blast furnace-basic oxygen furnace (BF-BOF) method. This process is responsible for approximately 7-9% of global CO₂ emissions. Additionally, steel production consumes vast amounts of water and generates byproducts such as slag and dust, contributing to pollution. Addressing these challenges is crucial for achieving environmental sustainability.

Key Innovations in Sustainable Steel Production

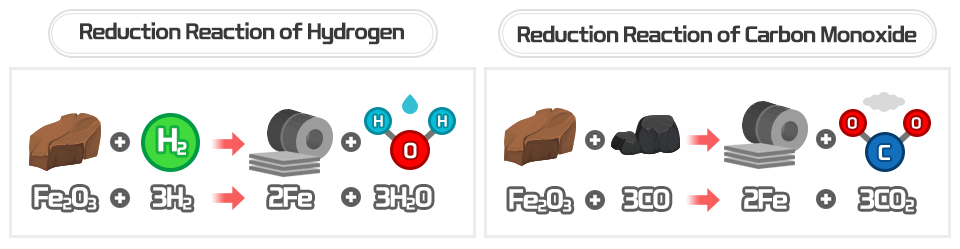

- Hydrogen-Based Steelmaking

One of the most promising breakthroughs in green steel production is the use of hydrogen instead of coal. In Hydrogen Direct Reduction (HDR) technology, hydrogen replaces coke in the iron ore reduction process, resulting in water vapor emissions instead of CO₂. Companies like SSAB, ArcelorMittal, and Thyssenkrupp are investing in hydrogen-based steel production, aiming to achieve carbon neutrality.

Benefits of Hydrogen Steelmaking:

- Eliminates CO₂ emissions from iron ore reduction

- Uses renewable hydrogen produced via electrolysis

- Reduces dependence on fossil fuels in steel production

2. Electric Arc Furnaces (EAF)

Electric Arc Furnaces (EAF) use recycled scrap steel instead of raw iron ore, significantly lowering energy consumption and emissions. Powered by renewable electricity, EAF technology can produce high-quality steel with minimal environmental impact.

Advantages of EAF Technology:

- Consumes less energy than traditional blast furnaces

- Utilizes up to 100% recycled steel, reducing mining impact

- Can be integrated with renewable energy sources, such as solar or wind power

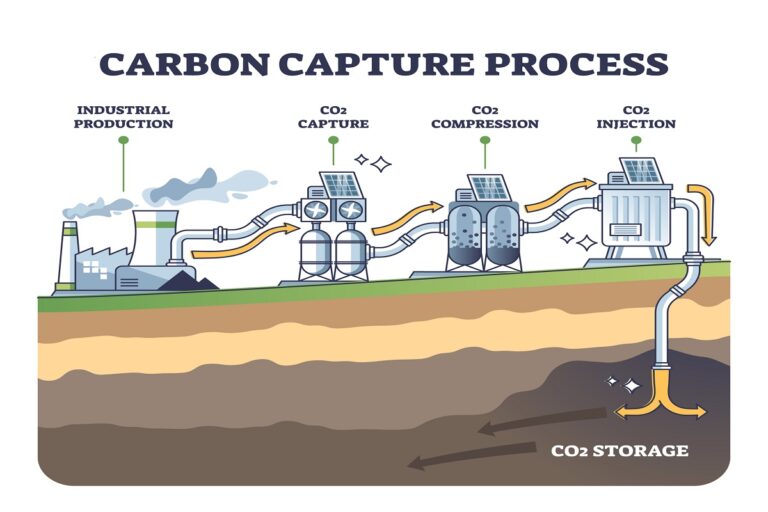

3. Carbon Capture and Storage (CCS)

While transitioning to fully green steelmaking methods will take time, Carbon Capture and Storage (CCS) offers a viable interim solution. CCS captures CO₂ emissions from steel plants and either reuses or stores them underground, preventing them from entering the atmosphere.

Key Benefits of CCS:

- Reduces overall CO₂ footprint of existing steel plants

- Compatible with current steelmaking technologies

- Can be implemented in various industrial sectors

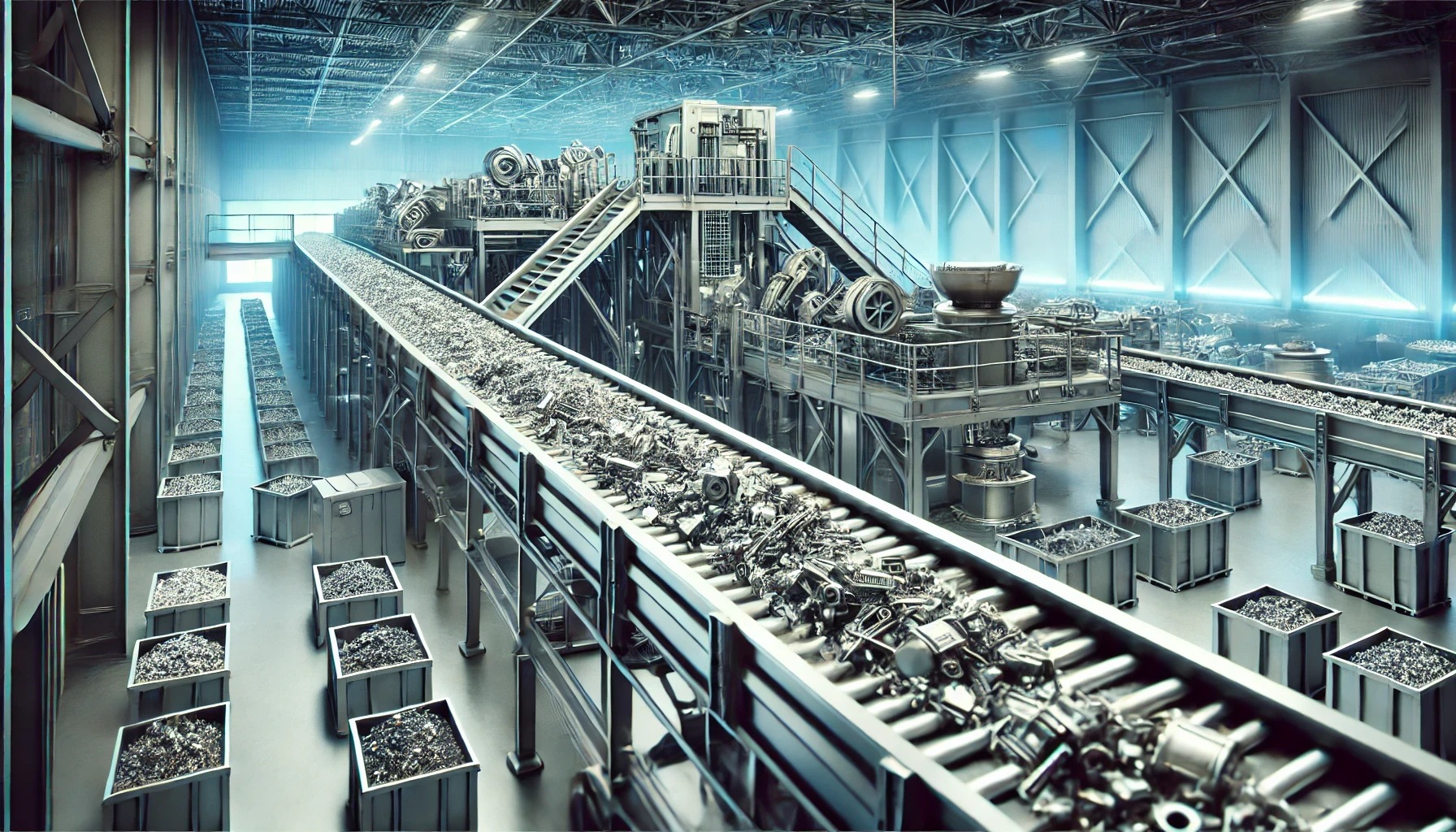

4. Circular Economy and Steel Recycling

Recycling steel is one of the most effective ways to make the industry more sustainable. Steel is 100% recyclable, meaning it can be reused indefinitely without losing its properties. The shift towards a circular economy—where materials are continuously reused and repurposed—reduces reliance on virgin iron ore and decreases waste generation.

Sustainability Benefits of Steel Recycling:

- Reduces raw material extraction

- Cuts down CO₂ emissions by up to 60-70%

- Consumes less energy compared to primary steel production

5. Biomass and Alternative Fuels

Replacing fossil fuels with biomass-based carbon sources, such as charcoal and bio-coke, presents another opportunity for sustainable steelmaking. Research is also exploring the use of alternative fuels, like ammonia and synthetic gases, to further cut emissions.

Potential Advantages:

- Lower net carbon emissions compared to traditional coal

- Utilizes renewable feedstocks

- Can be integrated into existing production processes

5. Smart Manufacturing and AI Optimization

Industry 4.0 is playing a critical role in reducing waste and improving efficiency in steel production. Artificial intelligence (AI), machine learning, and automation help optimize resource utilization, reduce defects, and enhance process control.

How Smart Manufacturing Supports Sustainability:

- Predicts and minimizes energy consumption

- Reduces material waste by improving precision

- Enhances supply chain efficiency, lowering carbon footprint

The Future of Sustainable Steel

The steel industry is at a pivotal moment, with increasing regulatory pressure and growing consumer demand for low-carbon materials. Companies investing in sustainable innovations are positioning themselves as leaders in the green industrial revolution. While the transition to fully green steel production may take decades, continued advancements in hydrogen steelmaking, electric arc furnaces, and carbon capture will drive progress toward a cleaner, more sustainable future.

Conclusion

Sustainability in steel production is no longer an option—it is a necessity. By leveraging hydrogen-based processes, electric arc furnaces, carbon capture, recycling, and AI-driven optimizations, the industry can significantly reduce its environmental impact while meeting global steel demand. Governments, manufacturers, and consumers must collaborate to accelerate the adoption of eco-friendly technologies and ensure that steel remains a strong yet sustainable foundation for modern society.

As we move toward a greener future, embracing sustainable steel innovations will be key to achieving a low-carbon, resource-efficient, and environmentally responsible industrial ecosystem.