Here are a few rules to follow to ensure the effective use of an OES Spectrometer.

Sample Preparation: Sampling / Sample preparation is very important for getting good, stable, accurate & precise analysis results

Argon Gas: The Quality of Argon gas should be 99.9995% pure. No compromise on Argon Quality use only Spectro Grade like XL Grade/UHP grade.

Machine Stabilization: Give the Proper Stabilization Time. Follow the Daily Start-up Procedures. The LAB environment should be favourable as per the need of the instrument.

Standardization: The instrument should be recently standardized following the procedures. And has to be cross-verified using the CRM / Check Sample

It is a technique of obtaining the coin sample from the furnace to know the chemical composition of liquid metal before casting by Optical Emission Spectrometer. Tons of Liquid metal chemistry is decided by the small <100gram coin sample. So, it is very important to get a sound coin sample which shall duplicate the liquid metal in the furnace.

The following shall be done before getting the Coin Sample from the furnace.

- The Liquid metal shall be properly mixed.

- The Liquid metal shall be purged with Purge gas (Nitrogen)

- Remove the slag properly on the top of the Liquid metal.

- The Lollypop sample/coin sample is taken at the proper depth.

The above liquid metal is poured in a proper made of Cast Iron block for Aluminum or

Copper Block for steel and iron sample to obtain the Coin/Mushroom chill cast sample.

The sample thus obtained needs to be freshly prepared for Spectro Analysis.

It is very important for getting a good, stable, accurate and precise Spectro Analysis report the sample must be

- Homogeneous

- The analysing area / prepared area must be Flat /single-plane

- Free from Pin Holes

- Free from oil/dust/moisture and other foreign bodies

- Freshly prepare

- Prepared portion not to be touched.

- Not to rub with any cloth

Why Argon

Inert Gas:

Displace Oxygen:

Abundant:

Cheap:

Instrument Stabilization

For the Routine Operation after the Instrument is turned ON the Optical System temperature is stabilized using the internal heating system. It normally takes 15 to 20 Mins to reach the required temperature.

Also, the Argon Gas is turned ON to flush out the atmospheric air in the Optical Chamber and fill the chamber with Argon which acts as the medium for the light emitted from the sample sparking.

Once the Optical System is stabilised few Rough Sparks have to be taken to remove the contaminants in the Spark Chamber.

Even after these processes are completed before starting the Analysis it is recommended to verify the instrument using a Check Sample. If variation is seen in the results then the instrument has to be Standardised.

Standardization

What, Why & When

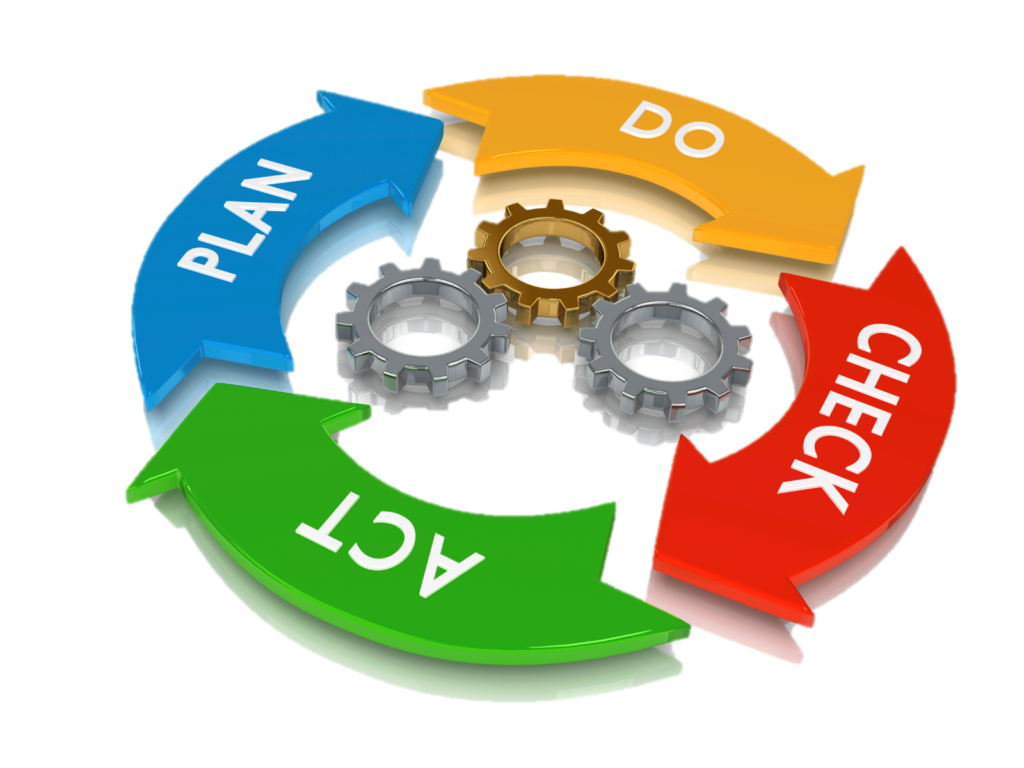

What is Standardisation?

Why Standardisation is Required?

When to do Standardisation?

- When you switch on the Instrument after a long shutdown. You have to start with standardization.

- Every 40kg drop in Argon Cylinder pressure

- When you clean the Spark Chamber or optical entrance window.

- If Check Sample / Certified Reference Material not giving correct result.

- In simple whenever you make any change to your spectrometer, you have to do standardization to get stable and repeatable results.

Homogeneous & Heterogeneous Sample

Homogeneity and heterogeneity are concepts relating to the uniformity of a substance.

A homogeneous material is uniform in composition or character.

Examples of Homogeneous sample CRM, SUS, Secondary Standard, Chill Cast Coin sample, Rolled bars ……

One that is heterogeneous is distinctly non-uniform in one of these qualities.

Examples of Heterogeneous sample Casting, are INGOT sample, ASH CAST sample….

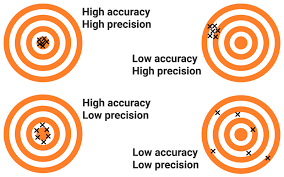

Accuracy and Precision

Precision is the closeness of the measurements to each other. The precision of a measurement system refers to how close the agreement is between repeated measurements.

Repeatability and Reproducibility

Reproducibility is simply the precision determined under conditions where the same methods but different equipment are used by different operators to make measurements on identical specimens.

Error

SUS & CRM

SUS

CRM

Check Sample / Secondary Master

Why you NEED a Spectrometer!

Profitability

COSTOVATION in True Sense!

Nickel is an important element in Stainless-Steel Production, so in order to avoid rejection if you don’t have a spectrometer you’ll add an extra quantity in the furnace which will cost you more for the production.

Even if we consider a 1 Ton of Production and even if you save 1% of Nickel you will be saving 10,650 per Ton. Also, the cost of the Instrument will be recovered within a span of 1 year.

Quality

Compliance

Prevents Rejection