In the world of metallurgy and material science, accurate analysis of cast iron is critical for ensuring quality, performance, and consistency in manufacturing processes. One of the most reliable methods for analysing the elemental composition of cast iron is Optical Emission Spectroscopy (OES). However, the accuracy of OES analysis heavily depends on the quality of the sample being tested. This is where the Chill Cast Coin Sample comes into play. In this blog, we’ll explore why chill cast coin samples are indispensable for OES analysis in cast iron and how they contribute to reliable and precise results.

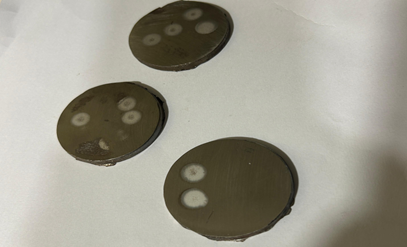

What is a Chill Cast Coin Sample?

A chill cast coin sample is a small, disc-shaped specimen of cast iron that is rapidly solidified using a chilled mold. The rapid cooling process creates a fine, uniform microstructure, which is ideal for spectroscopic analysis. These samples are typically standardized in size and shape to ensure consistency across tests.

Why is Chill Casting Important for OES Analysis?

OES analysis relies on the principle of exciting atoms in a sample to emit light, which is then analyzed to determine the elemental composition. For this method to work effectively, the sample must be homogeneous and representative of the bulk material. Here’s why chill-cast coin samples are so important:

Uniform Microstructure for Accurate Analysis

- Chill casting promotes rapid solidification, resulting in a fine and uniform microstructure.

- This uniformity ensures that the sample is free from irregularities, such as large graphite flakes or carbide formations, which can skew OES results.

- A consistent microstructure allows for precise and repeatable measurements of elemental composition.

Minimized Segregation of Elements

- In cast iron, elements like carbon, silicon, and manganese tend to segregate during slow cooling, leading to uneven distribution.

- Chill casting reduces this segregation, ensuring that the sample accurately reflects the overall composition of the cast iron.

Enhanced Detection of Trace Elements (boron, lead, bismuth, titanium, manganese, sulphur, and phosphorus)

- The fine-grained structure of chill-cast samples improves the detection of trace elements, which might otherwise be difficult to measure in slower-cooled samples.

- This is particularly important for quality control, as even small amounts of certain elements can significantly impact the properties of cast iron.

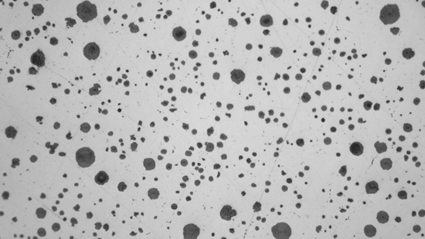

Reduced Graphite Interference

- Graphite formation is a common characteristic of cast iron, but it can interfere with OES analysis by causing inconsistent spark patterns.

Chill casting suppresses graphite formation, providing a cleaner matrix for analysis and ensuring more reliable results.

Reproducibility and Standardization

- Chill cast coin samples are standardized in size, shape, and preparation method, making them ideal for reproducible testing.

- This consistency is critical for quality control, allowing manufacturers to compare results over time and across different batches.

Compliance with Industry Standards

- Many industry standards, such as those set by ASTM and ISO, recommend or require the use of chill cast samples for OES analysis of cast iron.

- Using chill cast samples ensures that testing procedures align with recognized best practices, enhancing the credibility of the results.

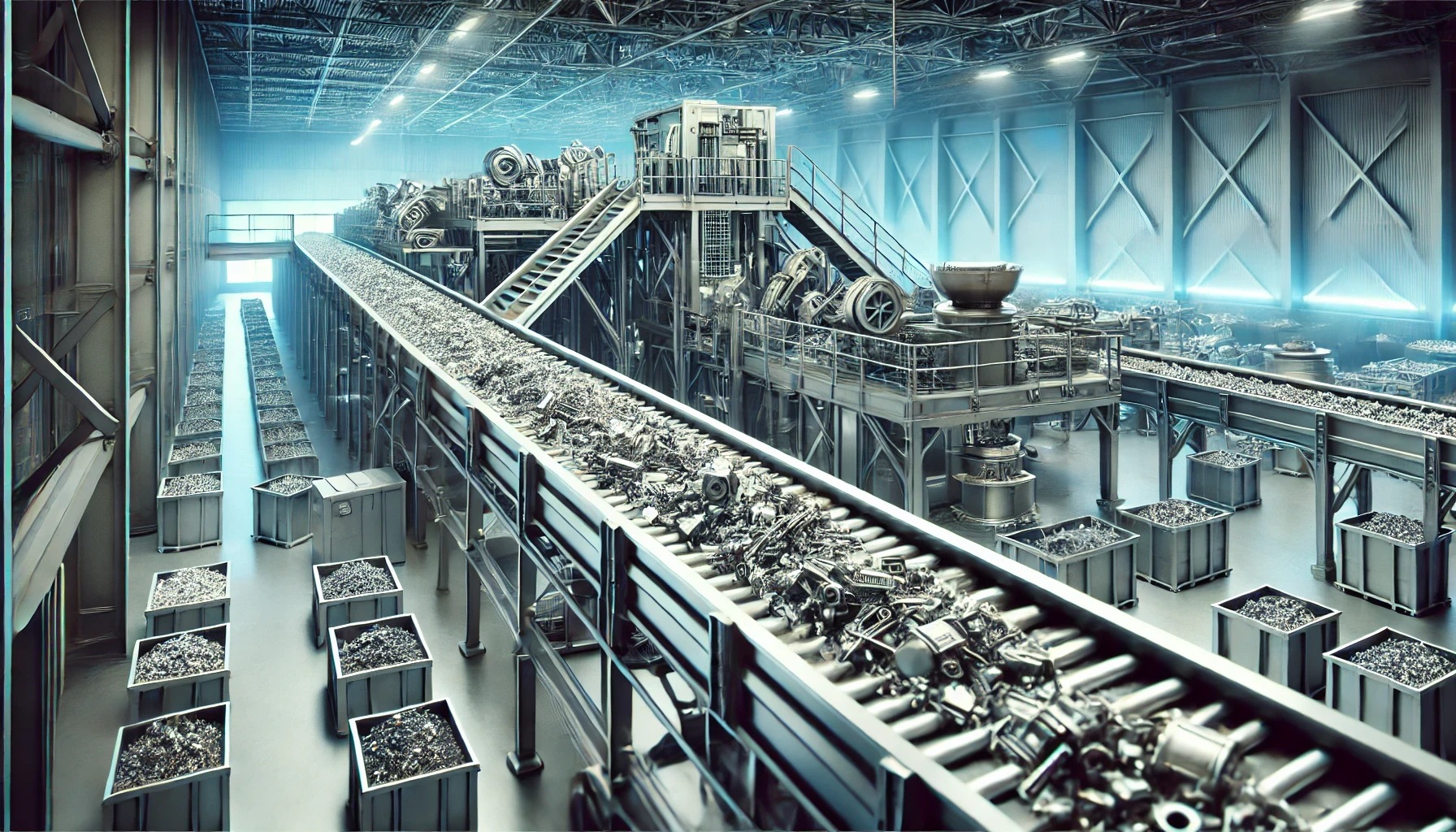

Applications of Chill Cast Coin Samples in Industry

Chill cast coin samples are widely used in industries where cast iron is a key material, including:

Automotive Manufacturing- For analyzing engine blocks, brake discs, and other cast iron components.

- Pipe and Fitting Production: To ensure the quality and durability of cast iron pipes.

- Machinery and Equipment: For testing gears, housings, and other cast iron parts.

- Research and Development: To study the effects of different alloying elements on cast iron properties.

By providing accurate and reliable data, chill cast coin samples help manufacturers maintain high standards of quality and performance.

Conclusion

Using chill cast coin samples in OES analysis ensures greater accuracy, consistency, and reproducibility in cast iron composition measurement. It eliminates microstructural inconsistencies, minimizes graphite interference, and standardizes the testing process, making it an essential step in metallurgical quality control.

Let’s embrace precision and reliability in cast iron analysis—one chill cast coin sample at a time!